Finding the right manufacturer for thermoforming molds can be a critical step in bringing your custom product ideas to life. China is home to numerous high-quality manufacturers specializing in vacuum forming molds and thermoforming tools. Whether you’re looking for a vacuum forming molds supplier or a thermoforming molds manufacturer, the process of securing a sample can help you ensure quality and precision before moving forward with large-scale production. Here’s a guide on how to efficiently get a sample from thermoforming molds China and optimize your production workflow.

Identifying the Right Thermoforming Molds Manufacturer

Before you can request a sample, you must first identify the right vacuum forming molds manufacturer. Start by conducting research into potential vacuum forming molds suppliers who specialize in your specific needs—whether that’s custom vacuum forming molds, bespoken vacuum forming molds, or even vacuum forming 3D printed molds. Look for manufacturers with a proven track record in your industry. Check online reviews, ask for references, and review their portfolios to ensure their capability aligns with your requirements.

Ensure that the thermoforming molds supplier offers the types of thermoforming molds you need, such as vacuum forming mold design or vacuum forming molding machines. A manufacturer with advanced equipment and experience in making vacuum forming tools and thermoforming tools will be able to meet your quality and design expectations.

Requesting a Sample of Thermoforming Molds

Once you have narrowed down your list of potential thermoforming molds China manufacturers, the next step is to reach out and request a sample. Many vacuum forming molds suppliers will be willing to provide a sample for an initial evaluation. To request a sample, you’ll need to provide the mold vacuum forming design specifications, including the material, dimensions, and any unique features required for your product. If you need custom thermoforming molds, this is the time to specify the exact details of your product.

Some manufacturers may charge a fee for the sample, which can be used toward the final cost if you proceed with a full production order. Ensure you confirm whether the sample includes testing and evaluation, especially if you plan to conduct further design alterations based on the sample’s performance.

Evaluating the Sample for Quality and Precision

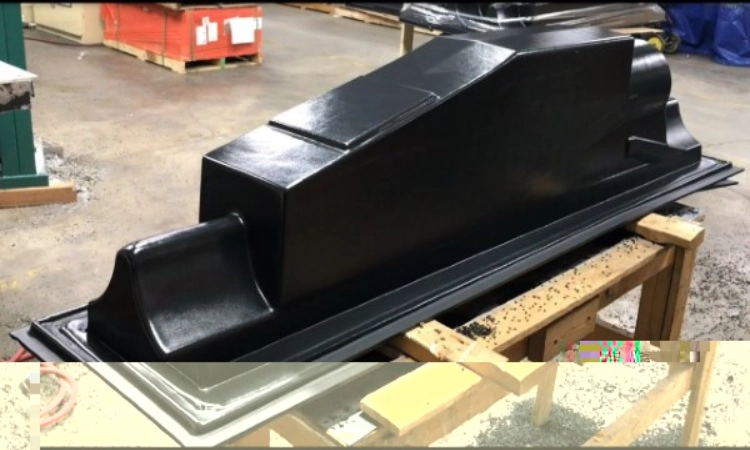

Once the sample is received, it’s essential to evaluate it thoroughly to ensure it meets your expectations and specifications. Test the vacuum forming mold materials used, as the material quality plays a significant role in the overall performance and durability of the product. Inspect the design for precision, particularly if you’re using vacuum forming tools or thermoforming tools that need to match tight tolerances.

Check how well the sample fits with your production process. This evaluation will allow you to assess the overall design and functionality of the thermoforming molds and ensure they are compatible with your vacuum forming molding machine. It’s also crucial to evaluate the mold’s ability to maintain integrity and quality under different production conditions. If the sample meets your standards, it’s time to move forward with full-scale manufacturing.

Finalizing the Order and Production

Once you’ve received the sample and verified its quality, the next step is to finalize your order. Contact your thermoforming molds manufacturer to discuss production timelines, quantities, and any further customizations you may require. Whether you’re ordering custom thermoforming molds or a range of bespoken vacuum forming molds, ensure that the manufacturer is clear on all specifications. Be sure to confirm the costs involved, delivery timelines, and any additional services like mold maintenance or after-sales support.

If necessary, you can also request a 3D print vacuum form mold for additional design testing. As many manufacturers now offer vacuum forming 3D printed molds, this can be a cost-effective way to prototype and tweak your designs before moving to mass production.

In conclusion, working with a vacuum forming molds supplier in China requires careful research, clear communication, and attention to detail. By following these steps and collaborating closely with your thermoforming molds China manufacturer, you can ensure that you receive high-quality, precise samples that meet your exact needs. With the right approach, securing a sample and moving forward with production can be a smooth and effective process.